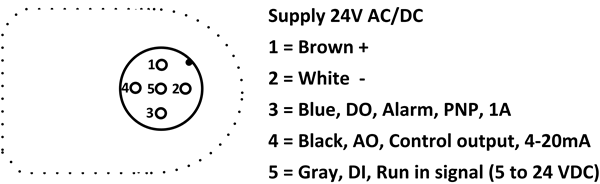

Technical data: HBAC-U

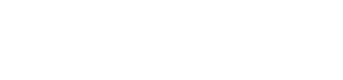

This sensor is versatile and can be used exclusively for leakage detection or for both oil return and leakage detection of CO2 into ammonia. It must be installed in the liquid ammonia circuit. When positioned in a low location where oil collects, it can manage oil levels and detect CO2 leaks into the ammonia circuit, functioning similarly to the HBSR but based on the mA signal.

If CO2 leaks into the ammonia part, it forms ammonium carbamate, a highly corrosive salt that clogs the system and can take weeks to remove. Failure to address this in time can cause significant downtime and damage to the entire ammonia system.

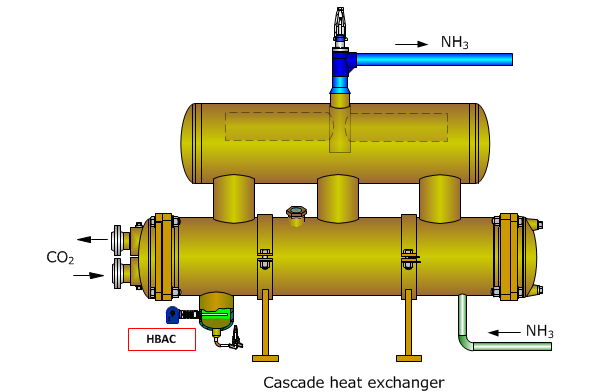

The sensor provides a digital alarm output and an increased mA output when ammonium carbamate is detected in the ammonia. For optimal detection, the sensor should be installed in the liquid ammonia at the bottom of the vessel, as ammonium carbamate is heavier than ammonia. However, it can be installed in any position as long as it is covered by liquid ammonia.