Technical data: HBCP

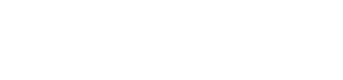

The Compressor Protection Sensor is a DX version of the HBX Vapor Quality Sensor, designed for installation at the compressor inlet. It detects when liquid content in the gas exceeds a critical threshold, sending an alarm and measured value to a PLC. This data helps control the system and prevent liquid slugging by stopping the compressor when necessary.

The sensor reduces the risk of damage and breakdowns by preventing liquid refrigerant from entering the compressor. It's particularly useful in larger systems with multiple evaporators, offering monitoring and troubleshooting capabilities. The Vapor Quality Sensor provides instant feedback by measuring the liquid in the gas flow.

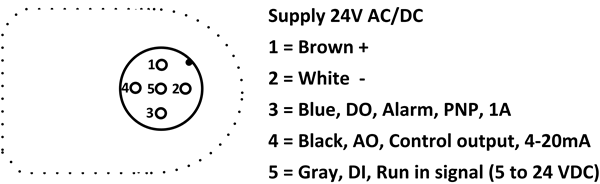

Available versions include:

Rod Style: Installed in an elbow at the bottom of horizontal pipes, with 200 mm and 300 mm options for pipes up to 4”.

Inline: For both horizontal and vertical pipes, available up to DN100.

Strainer House: Installed in a downward elbow in an empty strainer house, detecting liquid on the walls.