Category: HBX-DX

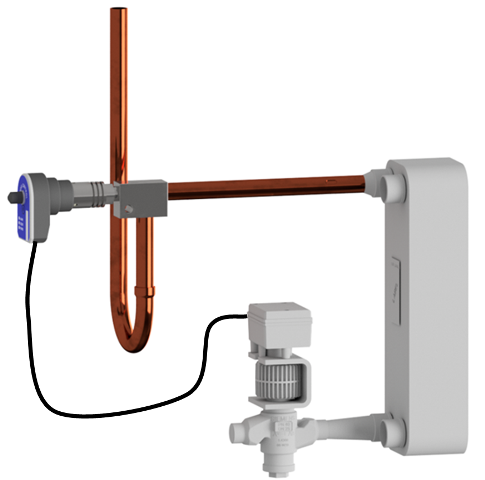

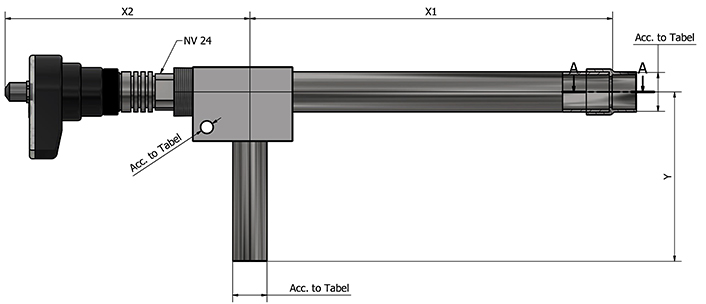

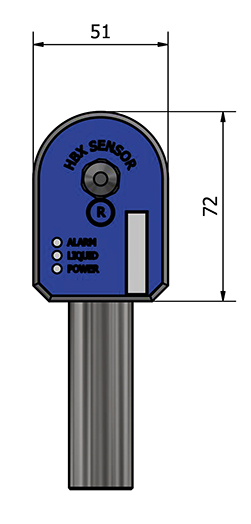

The angle rod version is a compact and durable sensor designed for smaller refrigeration systems. Made from stainless steel, it is suitable for all common liquids and accepts flow in both directions.

The sensor is equipped with reductions to compensate for a restricted flow area, ensuring optimal performance. Installation options include butt welding (TIG) or brazing, and the sensor element can be removed for cleaning if needed.