Technical data:

HBX-DX-R-EX - ATEX/IECEx Certified

HB products has developed the unique vapor quality sensor, which is the only sensor able to directly measure the liquid content of liquid in the evaporator output. The sensor works both in pump circulated and DX systems and can optimize the efficiency and capacity to a new level.

Evaporator control

The optimal evaporator is not filled with liquid refrigerant like you often have in pump circulated refrigerant systems with circulation ratios above 1.5. The optimal evaporator is not dry like a lot of superheat-controlled evaporators.

By measuring the liquid content in the evaporator output and using this measurement to control the liquid feed.

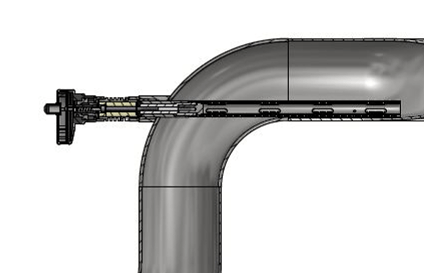

Most refrigeration systems operate most of the time in part load and especially during part load the efficiency is typically rather poor and can be optimized significantly. Pump circulated systems fills the evaporator with liquid which reduce heat transfer by 50 % and increases the pressure loss which increase energy consumption. For pump circulated systems an energy saving of minimum 20% is typical for optimized systems, and much more on systems without circulation control.

In DX systems a larger part of the evaporator is used for superheating and the superheat is increased which reduce capacity and increase the power consumption dramatically. We have documentation showing an energy saving of 20% during full load and 50% during part load for a DX ammonia system. Link to the documentation.

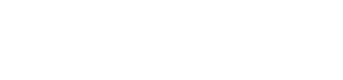

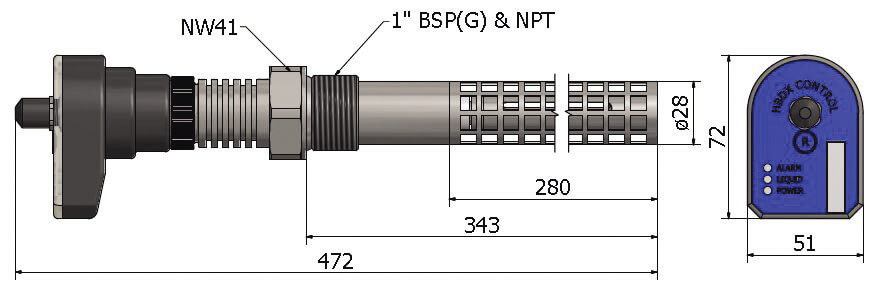

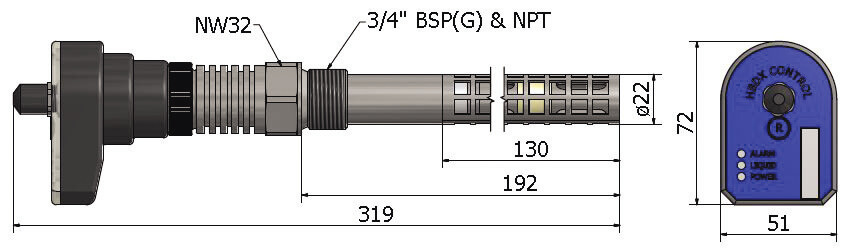

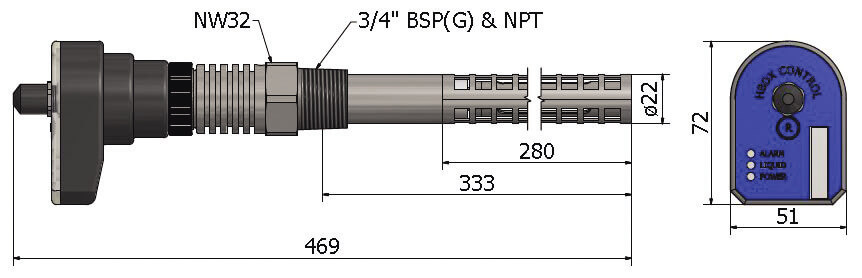

Rod style version

The rod style sensor has been on the market for several years and works well if it is installed correctly. This sensor only measures the liquid inside the sensor element itself, and not like the other types between the inner element and the pipe walls. This means the sensor must be installed where the liquid flows at the bottom of a horizontal pipe. The sensor must be installed in an elbow with the sensor element located at the bottom of a horizontal pipe.

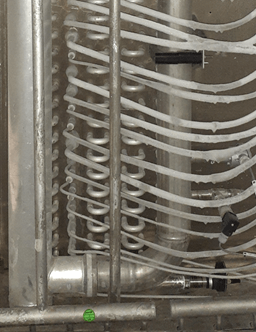

Intrinsically Safe design

Intrinsically Safe (IS) sensors are designed and wired to work on such a low current and voltage that it cannot possibly ignite flammable material. By limiting the energy available within the defined hazardous area, electrical equipment can operate safely even amid hazardous mixtures of gasses.

Product selection guide

To find the right part number to purchase please use our selection guide in the shop (link below), product overview under "ordering code" or send our Product Manager Henrik Kudsk a system description and he will guide you to the right part number. Please use the "Product Specification Form" (find it under the "downloads" tab on this product page) and e-mail it to sales@hbproducts.dk

Spanish

Spanish  English

English  German

German