Technical data: HBLT-W3-Wire & HBSLT-W3-Wire

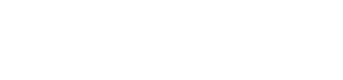

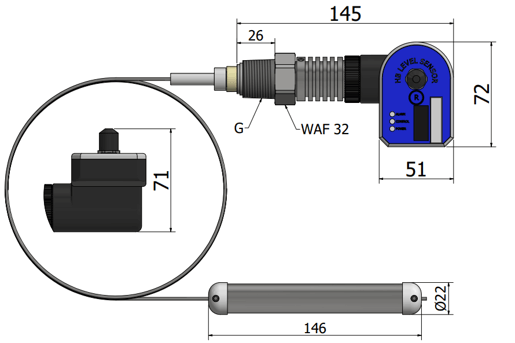

The HBLT-W3-Wire and HBSLT-W3-Wire are innovative capacitive Wire Sensors designed for accurate liquid level measurement in industrial refrigeration systems. Built with a 1,5 mm insulated stainless steel wire, they can withstand high pressure and low temperatures, providing a reliable and durable solution.

Key features

- Liquid temperature range: Operate across a temperature range of -60°C to 60°C (-76°F to 140°F).

- Pressure tolerance: Rated for pressures up to 100 bar (1450 psi).

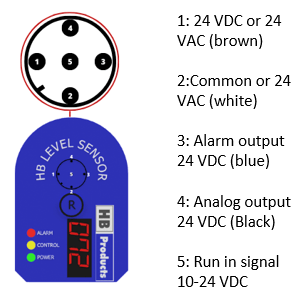

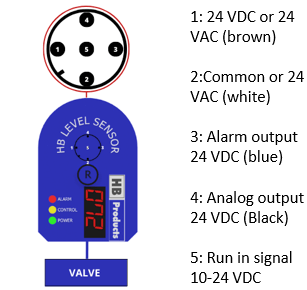

- Power supply: The sensor operates on a 24 V DC power supply.

- Flexible length: The sensor wire can be adjusted from 250 mm to 6000 mm, providing flexibility for various applications

- LED indicators: Provides clear visual indicators for power supply and alarm status.

- Split design: Simplifies installation and diagnostics; electronic parts can be removed with two screws.

- Easy configuration: Configuration with a PC using HB Tool software.

Please be aware: If the sensor is to be used in water or other liquid-conducting fluids where high accuracy is crucial, a special kit is required. This kit serves to seal the open end of the wire, thereby eliminating electrical contact.

Spanish

Spanish  French

French  German

German