Technical data: HBSR

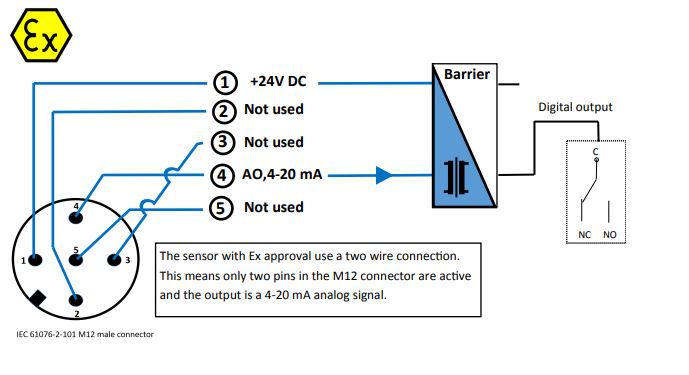

HBSR is a level switch for detecting liquids. It is calibrated in such a way that splash water and foaming cannot harm it. The sensor is made of stainless steel and can therefore also be used in corrosive environments. It withstands high pressures and low temperatures. The HBSR may only be used in steel tanks or steel pipes.

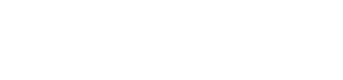

The switch must be supplied with 24 V DC power across an Ex barrier. This barrier must be an approved and certified galvanically isolated interface barrier located outside the hazardous area. The switch is a 2-wire version with an analog output with 4 mA (no liquid detection) and 20 mA (liquid detection). The digital input must be connected to the Ex barrier. The Ex barrier is not included.

The sensor can be adapted to the respective liquid type using our HB tool, which you can download from our website. See HB Tool. In addition, the HB Tool can also be used to switch between NC and closing contacts. Diagnoses can also be carried out with the tool. Programming must be carried out outside the danger zone.

According to ATEX/IECEx, the sensor range includes sensors for zones 0 and 1. The sensors can be used in device category 1G and temperature class T1... T6.

A 5 m long cable with an M12 connector of type IEC61076-2-101 is included in the scope of delivery.

Spanish

Spanish  French

French  German

German