Technical data: HBLT-W3-Wire & HBSLT-W3-Wire

HBLT-W3-Wire and HBSLT-W3-Wire are the latest version of capacitive wire sensors for liquid level measurement. The sensor is typically used in industrial refrigeration systems and other industrial applications. They are useable in ammonia, HFC/HFO/CFC, and water but not in oil, hydrocarbons, and CO2. For these liquids with a low dielectric constant the HBLT-FLEX must be used.

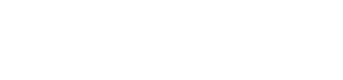

The sensor has no dead zone and can be used for lengths from 250 mm to 4 or 6 m. It must be installed in a standpipe or in a pipe built into a vessel with a diameter from DN 25 to DN100 (1” to 4 “).

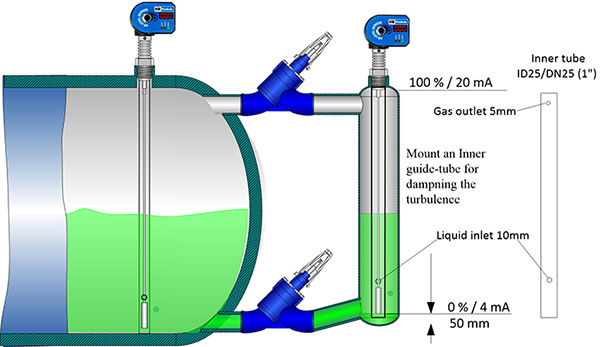

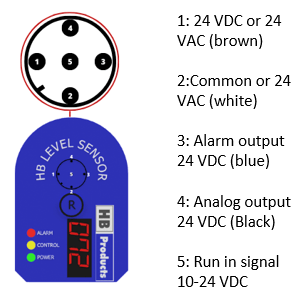

Both sensors have a 4-20 mA analog output signal, which is proportional to the liquid level. Its output signal is 4 mA for an empty container and 20 mA for a full container.

The HBSLT has a built-in controller and a cable output supplementing the M12 output. This cable is used for direct valve control. Alternatively, HBLT-W-Wire can be used in connection with the HBLT-C1 controller or a PLC for controlling pumps and valves.

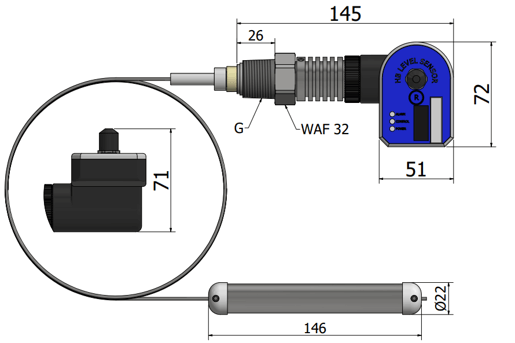

The sensor element consists of a 1.5mm insulated stainless steel wire. The wire is provided in 4 or 6 m length and can be shortened on site with diagonal cutters or other pliers. When cut to length the sensor must be setup to the actual length by using the HB tool.

This latest version has a new counterweight where the wire pass through without electrical connection. This construction ensures a linear measurement all the way from the end of the wire below the counterweight to the top.

If the sensor must be used in water or other liquid conducting fluids and high accuracy is needed a special kit is needed. The function of the kit is to close the open end of the wire to eliminate the electrical contact.

Spanish

Spanish  French

French  German

German