46 % improvement of SEPR obtained by replacing a conventional superheat control with a control based on vapor quality technology. A 100-kW chiller operating with R717 using direct expansion is tested at Karlsruhe as a bachelor and master project.

Most chillers and heat pumps constructed as direct expansion plants use the conventional control based on temperature and pressure of the gas leaving the evaporator. An alternative to the conventional approach is to use a Vapor Quality Sensor, which can measure the content of liquid in the gas leaving the evaporator. When controlling the expansion valve based on the vapor quality, superheat can be eliminated and the heat transfer improved, which improves the COP.

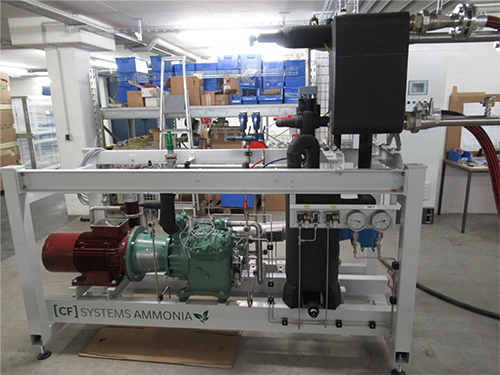

It can be difficult to test and compare the two control methods on plants that often are uniquely designed. Therefore, the best result is obtained in a testing environment. At Hochschule Karlsruhe the student has built and tested a chiller with the two different control systems. The chiller can be operated with both control systems and it is easy to switch between the two systems and measure the difference.

The chiller is designed with two plate heat exchangers operating as evaporator and condenser both liquid heated/cooled. The charge is 4 kg ammonia (R717) and the capacity is 100 kW. The temperature settings are made to match 2016/2281 regulation following the EU Ecodesign directive making it comparable to other chillers. The output of the chiller is 12/7 °C according to the standard.

| Measured values for ammonia-based chiller |

| SEPR | Full load COP | Part load COP | Unit | Yearly energy consumption | |

| Superheat 8K control | 5.6 | 3.9 | 6.9 | kW/kW | 91.086 kWh |

| Vapor Quality control | 8.2 | 4.7 | 10.5 | kW/kW | 63.140 kWh |

| Improvement | 46 | 21 | 51 | % | 27.946 kWh |

The table shows a fair improvement of 21% during full load but a huge saving of 51% in part load. The tests are done in accordance with the Ecodesign guidelines.

The chiller is tested at different capacities matching the SEPR (Seasonal Energy Performance Ratio) specifications both running with superheat control and with vapor quality-based control and the differences are significant. SEPR can be seen as a specific COP value, where the boundaries reflect the temperature variation over a year, making it a much better measurement.

The requirements for complying to the Ecodesign directive for a smaller chiller with water cooling is SEPR>6.5 until 2021 and 7 from 2012 onwards. This means the tested chiller comply with the Ecodesign requirements when using the vapor quality control but not when using the conventional control system.

| High temperature process chillers | From 01/2018 | From 01/2021 |

| SEPR 12/7" | SEPR 12/7" | |

| Air cooled < 400 kW | 4,5 | 5,00 |

| Air cooled 400 to 2000 kW | 5,00 | 5,50 |

| Water cooled < 400 kW | 6,50 | 7,00 |

| Water cooled 400 to 1500 kW | 7,50 | 8,00 |

| Water cooled 1500 to 2000 kW | 8,00 | 8,5 |

When vapor quality control is used, the annual energy consumption is reduced by 28 MWh equal to 3350 € based on the average EU electricity price for non-consumers (0.12€/kWh). Looking over a 10 years period the savings are in the same magnitude as the cost price for the complete chiller.